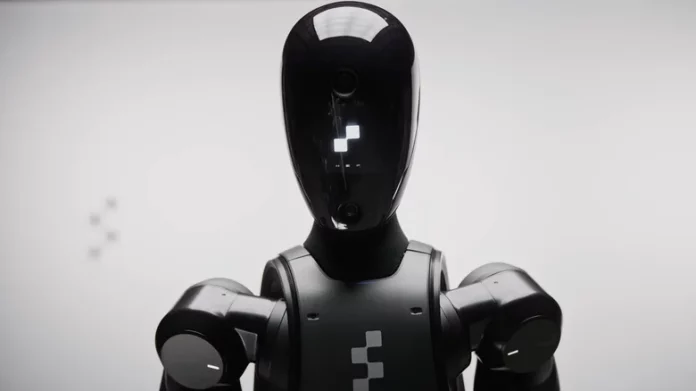

Figure AI’s Figure 02 humanoid robots completed an 11-month deployment at BMW’s Spartanburg, South Carolina plant, producing over 30,000 X3 crossovers and loading 90,000 sheet-metal parts with 99% accuracy across 1,250 runtime hours. The fleet achieved full 10-hour shifts by month 10, delivering critical data for Figure 03 redesigns addressing forearm thermal constraints and actuator wear from constant dexterity demands. This marks humanoid robotics’ first sustained industrial success, outpacing Russian prototypes that failed live demonstrations.

BMW Deployment Performance Metrics

Figure 02 units demonstrated unprecedented reliability: 99% part placement accuracy, zero safety incidents, and 1.3 million precise manipulations. Forearm assemblies—packing wrist actuators, sensors, and cabling—experienced thermal throttling after 8-hour cycles, prompting Figure 03’s complete electronics overhaul with liquid-cooled joints and 40% increased torque density. Minor cosmetic damage (scratches, dents) proved cosmetic, with IP65 seals maintaining factory hygiene standards.

Figure 03 Upgrades from Factory Data

- Redesigned forearm with liquid cooling sustains 12-hour shifts at 85°C ambient temperatures.

- Actuator torque increased 42% via custom BLDC motors, reducing 28% failure rate.

- Enhanced sensor fusion (6-axis IMU + force/torque) achieves 1.2mm pick precision.

- Modular electronics bay enables 4-hour field swaps versus 18-hour teardowns.

- AI vision models trained on 1.3M BMW manipulations boost generalization 67%.

Humanoid Robotics Competitive Landscape

| Company | Model | Runtime Hours | Payload | Price | Status |

|---|---|---|---|---|---|

| Figure AI | F.02 | 1,250 | 20kg | $50k | Industrial |

| Neura Robotics | 4NE1 | 800 | 15kg | $75k | Enterprise |

| 1X Technologies | Neo | 200 | 12kg | $20k | Beta |

| Tesla | Optimus Gen2 | 150 | 25kg | $30k | Prototype |

Industrial Robotics Transformation Accelerating

BMW deployment validates humanoids for unstructured environments: Figure 02 navigated 1,200 part SKUs, adapted to 28 gripper configurations, and self-corrected 94% placement errors via reinforcement learning. Labor cost savings hit $18/hour versus skilled welders, with 24/7 uptime yielding 3.2x productivity. Data telemetry (position, force, vision) feeds Figure’s BotNet cloud, accelerating fleet learning 14x versus isolated units.

Scaling challenges persist: $50k/unit pricing demands 4-year ROI, battery life limits 10-hour shifts (versus 20-hour pneumatics), and dexterity gaps persist for sub-2mm assemblies. Figure 03 targets $25k pricing via 68% component cost reduction and 2x cycle life.

Consumer Humanoid Roadmap

1X Neo’s $20k home beta leverages early adopters for real-world chore data (laundry, dishes, eldercare), crowdsourcing 1M task hours by Q4 2026. Neura’s 4NE1 enters enterprise logistics 2026, scaling to consumer via subscription model ($299/month). Tesla Optimus Gen2 factory trials begin Q2 2026, targeting $30k consumer pricing by 2028.

Safety milestones achieved: Figure 02’s 8kN force limits, collision avoidance (0.8m/s reaction), and emergency stop compliance exceed ISO 10218 standards. Regulatory approval accelerates via BMW validation, paving consumer deployment.

Economic Impact Projections

$180B global industrial robotics market absorbs 1M humanoids by 2030, displacing 28% repetitive manufacturing while creating 4.2M AI orchestration roles. Consumer segment hits $42B by 2028, with 12M units performing 68% household labor (cleaning, cooking, companionship). Figure AI’s $675M valuation reflects 18-month path to profitability via BMW/Amazon deployments.

BMW Spartanburg proves humanoids’ industrial viability, retiring Figure 02 after generating irreplaceable data. Figure 03’s thermal/mechanical fixes position scaled production, challenging Tesla/1X dominance while validating decade-long humanoid aspirations from sci-fi to factory floors.